SFF core vents are the only core vents with such a large number of parallel and uniform rectilinear openings

They ensure a high efficiency in the evacuation of gases (porosity ratio of 5 to 30 times higher than ordinary filters), hence a reduction in casting defects.

Increase of productivity (easy cleaning, reducing the frequency of core vents replacement)

Applications :

• Casting mold aluminum alloys (pores diam. 0,3 to 0,5 mm)

• Low pressure casting (pore 0,3 mm)

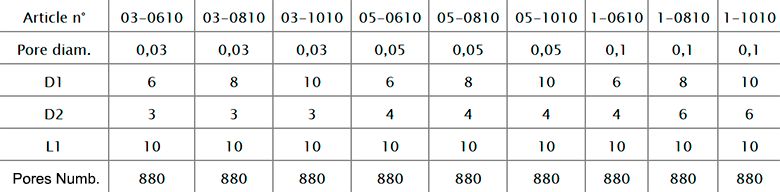

• Plastic injection molding (pores diam. 0,1 to 0,3 mm)

• Filtration unit

• Flow control system.

Number of pores per core vent = 1880 maxi.

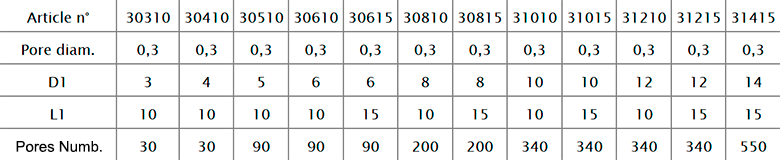

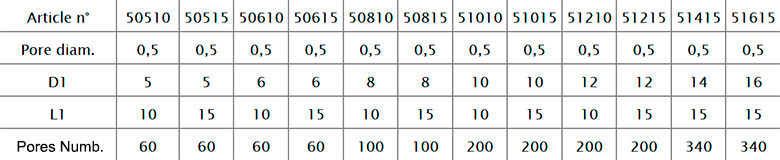

SFF for low pressure casting

SFF for gravity casting

SFF for plastic injection (currently unavailable)

Those new filters are used in low pressure casting of aluminium alloy. Height : 10 and 15 mm

![]()